Engineering Services

CBS’s fully equipped workshop, including state-of-the-art CNC facility, supplies formed metal products for use in diverse applications including gas fires, water heaters, cookers, warm-air heaters and infra-red burners. The flexible manufacturing facilities and continued investment in new technology enable us to accommodate both high-volume (up to 3000 units per week) and small, bespoke production for the assembly market.

Laser Cutting

With the introduction of our 2Kw Fibre Laser, we are now able to support a cost-effective and flexible approach to new product development, in addition to requirements for both flat-cut and formed parts.

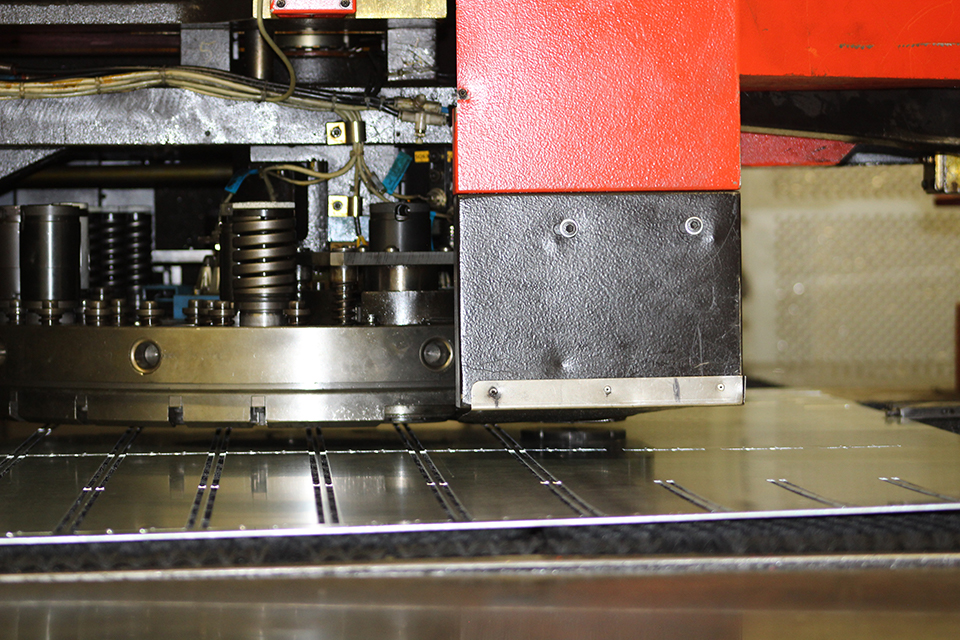

Press Work

A well established area of our production facility which enables us to offer additional services; from simple formed parts to more complex, fabricated assemblies.

Welding and Fabrication

With investment in state-of-the-art laser welding equipment, alongside our Tig and Mig process, CBS are able to offer a complete fabrication service, from small, intricate requirements to large, complex fabrications.

Painting and Plating

Our relationship with key finishing partners enables CBS to offer a complete service to the exacting requirements of a variety of industrial clients including: oil and gas, construction, automotive and pharmaceutical.